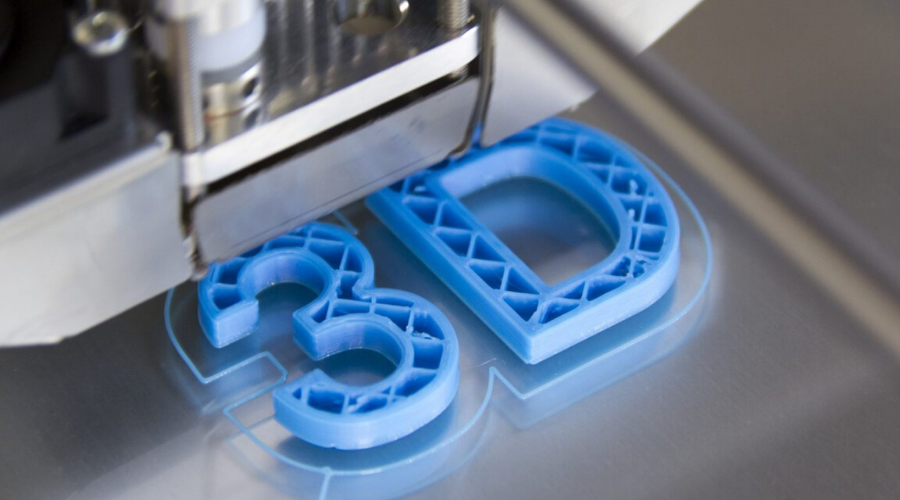

In the realm of modern technology, few innovations have captured the imagination quite like 3D printing. Often hailed as a revolution in manufacturing, this cutting-edge technology has transcended its early days as a niche concept to become a transformative force across a myriad of industries. In this article, we delve into the world of 3D printing, its evolution, and the profound impact it has had and continues to have on our lives.

A Glimpse into the Origins

The roots of 3D printing trace back to the 1980s when Chuck Hull, an American engineer, invented stereolithography, a process that allowed for the creation of three-dimensional objects layer by layer. Hull’s breakthrough laid the foundation for what we now know as 3D printing. Since then, the technology has evolved exponentially, with numerous printing techniques, materials, and applications emerging over the years.

Unleashing Creativity

One of the most exciting aspects of 3D printing is its potential for creativity and innovation. Unlike traditional manufacturing methods, which often involve subtracting material (such as carving or machining), 3D printing is an additive process. This means that designers and engineers can create complex, intricate, and customized objects without the constraints of traditional manufacturing.

From fashion designers crafting unique clothing and accessories to architects constructing intricate scale models, 3D printing allows for unparalleled creative expression. Artists, educators, and DIY enthusiasts have also embraced this technology, using it to bring their visions to life.

Revolutionizing Medicine

3D printing has made significant inroads into the medical field. Customized prosthetics, patient-specific implants, and even 3D-printed organs are no longer the stuff of science fiction. The ability to create personalized medical devices and implants has improved patient outcomes and quality of life while reducing surgery times and recovery periods.

Furthermore, medical researchers use 3D printing to create anatomical models for surgical planning and training, enhancing the precision and safety of complex procedures.

Transforming Aerospace and Automotive Industries

In aerospace and automotive industries, 3D printing has dramatically altered the landscape. Aircraft manufacturers are using 3D-printed components that are not only lighter but also more robust and efficient. This reduces fuel consumption and carbon emissions, pushing the boundaries of sustainability.

In the automotive sector, 3D printing enables rapid prototyping and customization of vehicle components. From concept cars to Formula 1 racing, automotive engineers have leveraged this technology to push the limits of design and performance.

Advancing Education

3D printing has also found a home in education. It is a powerful tool for teaching science, technology, engineering, and mathematics (STEM) concepts. Students can design, create, and test their own 3D-printed objects, promoting hands-on learning and problem-solving skills.

Sustainable Manufacturing

Sustainability is a pressing concern in today’s world, and 3D printing is playing a role in addressing it. By reducing material waste and energy consumption in the manufacturing process, 3D printing contributes to a more environmentally friendly production method.

Challenges and Future Frontiers

While 3D printing holds immense promise, it is not without its challenges. Issues such as material limitations, intellectual property concerns, and the need for industry standards must be addressed as the technology continues to evolve.

As we look to the future, we can expect even more remarkable developments in 3D printing. Researchers are exploring new materials, faster printing techniques, and larger-scale applications. The possibility of 3D-printed buildings, advanced electronics, and even food products is on the horizon.

In conclusion, 3D printing stands as a testament to human ingenuity, creativity, and innovation. It has reshaped the way we approach design, manufacturing, and healthcare. As the technology continues to mature, its influence will only expand, touching new facets of our lives and industries we can’t yet imagine. In this new era of manufacturing, the possibilities are as limitless as the human imagination itself.